Custom Rubber Molding

HOME >> CAPABILITIES >> Rubber Tooling

Rubber Tooling

Rich-Rubber: Expert Rubber Mold Development for Perfect Parts Every Time

We Build Smart Tools for Your Critical Rubber Components

Making top-notch rubber parts requires great molds. At Rich-Rubber, we create reliable, custom rubber molds for manufacturers in the automotive, medical, industrial, and consumer sectors. If you need a partner to craft the precise molds for your unique parts, we’re here to help. With years of experience under our belts, we provide complete rubber mold development solutions tailored just for you.

Your Custom Mold, Designed Right from the Start

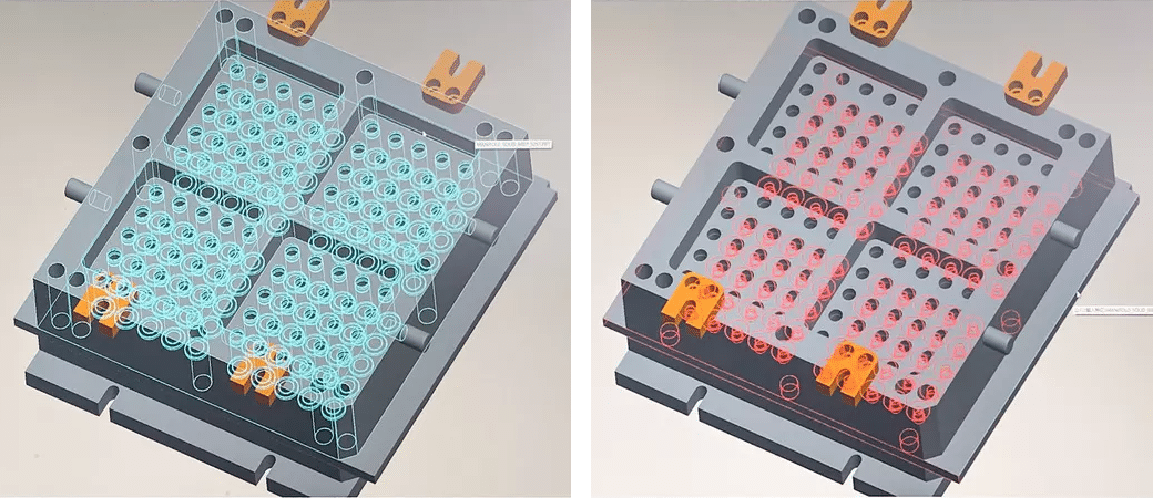

Our process always begins with design. Our team collaborates closely with you to understand exactly what your rubber part needs to do. Using the latest digital design tools, we create detailed mold plans on the computer. This virtual stage lets us check everything thoroughly, make adjustments easily, and tweak the design until it’s spot-on before we start cutting metal. This saves you time and money down the line, making sure the final mold will produce the exact part you want.

Test the Real Thing Before Full-Scale Production

Getting the design right on screen is crucial, but testing the actual rubber part is vital. That’s our next step: prototyping. We make real samples of your parts using the actual production molds we’ve designed. This practical test run lets everyone see, touch, and check how the part works. We can verify its size, shape, feel, and performance. Is it sealing correctly? Is the rubber flowing properly into the details? Our fast and efficient prototyping means you get samples quickly to make confident decisions. Only after you’re completely happy with the sample do we move ahead with full production, eliminating nasty surprises.

Modern Machines for Precise, Durable Molds

While Rich-Rubber focuses on design and project management, we guarantee top-quality mold production through deep collaboration. We work exclusively with proven specialists who operate the same advanced machinery trusted by leading manufacturers.

Think of it like this:

- Computer-Controlled Cutting (CNC): Our strategic production partners use industry-leading machines like those from Mazak, Fanuc, and Takumi. These partners transform tough steel blocks into highly accurate mold shapes, handling complex forms and tight details with proven consistency. This reliable approach gives you molds built to produce thousands of uniform parts.

- Electrical Spark Crafting (EDM): For challenging ultra-fine details or intricate geometries—like those needed for micro-seals or complex profiles—we engage trusted specialists using precision EDM technology such as TOP EDM. These partners utilize precision-spark etching to shape hardened steel exactly where traditional tools fall short, ensuring flawless replication of microscopic features.

- We select, certify, and actively oversee these partner facilities to meet our strict standards. This gives us—and therefore you—direct access to world-class mold-making capabilities without compromise. The result is the same robust, high-accuracy tool needed for your perfect rubber part: consistently manufactured, expertly managed, and thoroughly inspected before delivery to your production line.

Why Rich-Rubber for Your Mold Development?

Because getting your mold right is fundamental. By combining collaborative design, essential real-world prototyping, and high-precision manufacturing using proven advanced machinery, Rich-Rubber delivers dependable rubber mold solutions. We focus on turning your component ideas into physical molds that work efficiently and produce great rubber parts consistently. This allows us to meet your specific project needs, help manage costs, and support you in getting your final products to market effectively.

Ready for Molds Made Your Way?

Stop searching for the right mold partner. Contact Rich-Rubber today. Let’s discuss your project – whether it’s automotive seals, medical tubing, industrial dampers, or unique consumer product components. Together, we’ll design, prototype, and build the custom rubber molds you need to manufacture perfect parts consistently. Get started on your solution now.

Contact Us today to learn more about our custom rubber molding services and how we can help you with your next project.