Custom Rubber Molding

HOME >> CAPABILITIES >> Material Engineering and Rubber Mixing

Material Engineering and Rubber Mixing

Material Engineering & Precision Rubber Mixing: Your Performance Foundation

At Rich-Rubber, exceptional rubber parts start not at the mold, but in material science and the mastery of rubber mixing. We engineer solutions, not just manufacture parts. Our expertise transforms your unique application demands into consistently high-performing products through sophisticated formulation and controlled mixing processes.

Deep Material Science: Beyond Basic Blending

Creating effective rubber mixes isn’t simple blending. It demands profound expertise in polymer science – understanding their unique viscoelastic nature, interactions, and responses to temperature, pressure, and environmental stresses during mixing and final use. This knowledge lets us expertly manipulate fundamental building blocks. We meticulously select base polymers and orchestrate how reinforcing fillers, protective agents, and processing aids interact within the mix. This molecular engineering creates tailored material systems with specific, reliable properties designed to perform predictably under your precise conditions.

Mastering the Mix: Control Equals Consistency

Raw polymers, reinforcements, protective systems, and additives become high-performing materials only through precise mixing. This critical stage demands rigorous scientific control far beyond basic stirring. We meticulously manage temperature profiles throughout blending, calibrate shear forces per formulation, and optimize mixing times. Our goal? Flawless, uniform dispersion. Every particle must find its exact place within the rubber matrix. Achieving this level of uniformity is paramount. It guarantees batch-to-batch consistency, translating directly into reliable vulcanization behavior during molding, predictable material flow, and ultimately, uniform quality in your finished parts – eliminating unexpected failures.

Broad Material Capabilities, Targeted Solutions

Our engineering expertise spans the full spectrum of rubber materials. We expertly formulate mixes using:

- Versatile Natural Rubber (NR)

- oil-resistant Nitrile (NBR)

- Resilient EPDM for heat and weathering

- Versatile Neoprene (CR)

- hydrocarbon-resistant HNBR

- heat/oil resistant ACM

- Broad-temperature Silicone (SR)

- solvent-resistant FVMQ

- chemical/heat resistant Fluoroelastomers (FKM)

This extensive foundation enables us to select the optimal polymer base tailored to your specific rubber mixing requirements.

Engineering Your Perfect Mix

Our true strength is tailoring the rubber mixing precisely to your application. We start by deeply understanding your challenges: resisting specific oils/chemicals, enduring abrasion or high temperatures, maintaining flexibility in cold, ensuring seal integrity, combating UV/ozone degradation, meeting strict safety regulations (food, water, medical, electrical), or demanding electrical properties. With this insight, our engineers custom-design the mix, selecting the ideal polymer base and precisely fine-tuning additives and proportions to deliver exactly the performance profile your application demands. We engineer solutions, not offer standard catalog options.

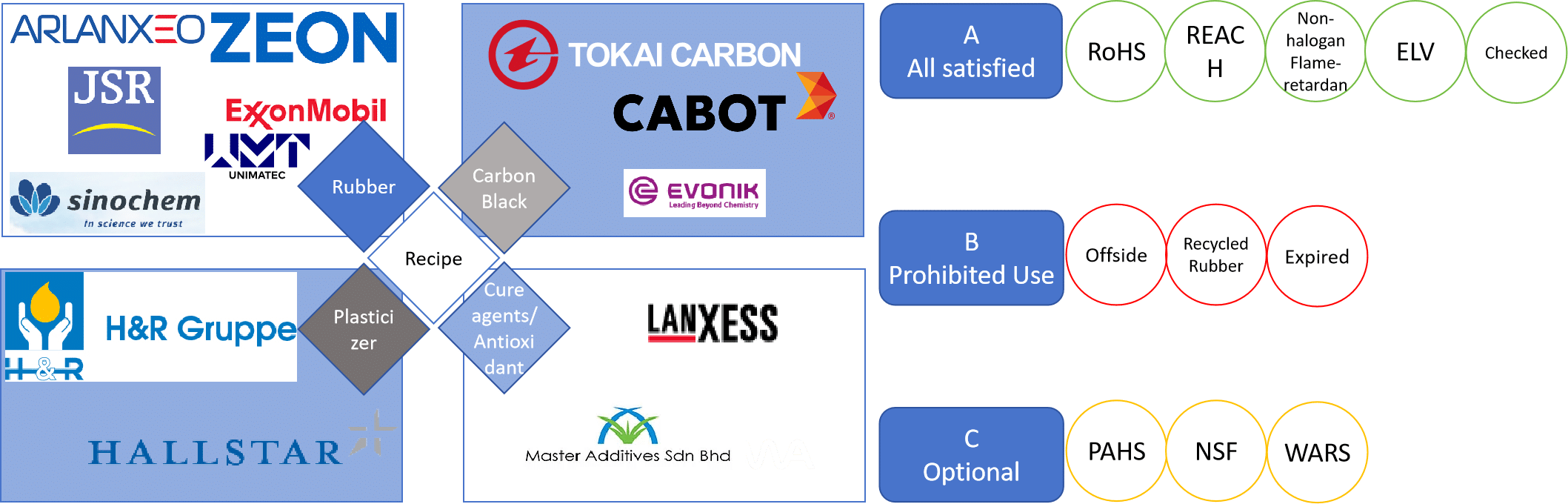

Quality & Compliance: Built-In Assurance

Performance is only part of the equation. Consistent quality and rigorous global compliance are fundamental to our promise. Our stringent quality system governs every mix, ensuring full batch traceability. We align with major international certifications – guaranteeing material safety for food contact, drinking water suitability, medical biocompatibility, electrical safety, and environmental responsibility. This embedded control gives you confidence for global markets.

Experience the Rich-Rubber Difference

Partner with engineers dedicated to performance. Share the demands your rubber parts face. We’ll collaborate to translate your needs into a custom-engineered rubber mixing solution, ensuring reliable performance and compliance. Contact Rich-Rubber today to see how our material science expertise and mixing mastery build the foundation for your product’s success.

Contact Us today to learn more about our custom rubber mixing services and how we can help you with your next project.