Beyond Plastic: How Rubber’s Strengths Are Redefining Modern Manufacturing

HOME >> News >> Beyond Plastic: How Rubber’s Strengths Are Redefining Modern Manufacturing

News

Beyond Plastic: How Rubber’s Strengths Are Redefining Modern Manufacturing

Author: Site Editor Publish Time: 07-01-2025 Origin: Site

The Quiet Rise of Rubber: Why It’s Outshining Plastic

Not long ago, plastic held the crown. It was the go-to material for nearly everything – shopping bags, toys, furniture, storage bins – you name it. It was affordable, versatile, and everywhere. But times change, and so have our priorities.

Today, as society shifts toward sustainability and confronts plastic’s long-term impact on the planet, we’re rethinking its role in manufacturing. Companies like Rich-Rubber, experts in rubber innovation, now lead the charge, offering alternatives that make many traditional plastics seem outdated.

Why Rubber? It Starts with Similarities…

At a microscopic level, rubber and plastic share DNA. Both are engineered from polymers and chemicals, meltable and moldable into any shape. Their differences lie in performance. While plastic once dominated on cost, modern rubber outperforms it in key areas critical to today’s challenges:

Strength That Adapts

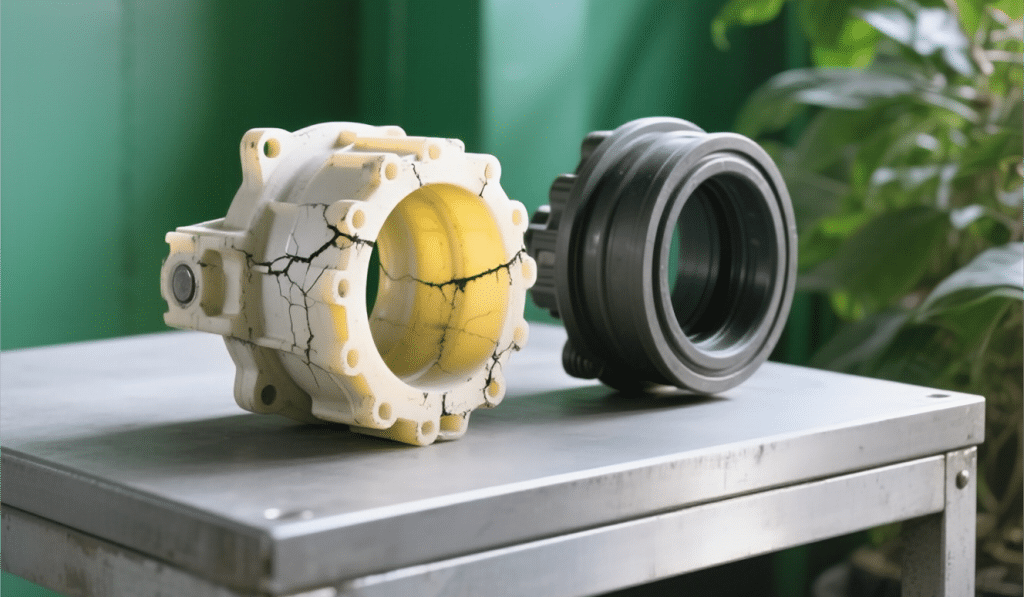

While some plastics mimic rubber’s flexibility, they often fall short in custom strength. Rubber compounds can be precision-engineered using processes like vulcanization or custom blending. Think of a durable rubber car part handling road vibrations for decades; plastics often crack under the same stress.

Mastering Extreme Temperatures

Plastics warp in intense heat and shatter in deep cold. Ever left a plastic tool outside in winter? Brittle disaster. Rubber, however, stays tough. Modern rubber formulations resist extreme temperatures – from scorching engine bays to Arctic equipment – keeping their shape and function intact.

The Sustainability Edge

This is where rubber truly shines. Plastic waste lingers for centuries – grocery bags and diapers taking 500+ years to decompose. Naturally derived rubber breaks down in ~1 year, and even advanced synthetic rubbers decompose faster than most plastics. For eco-driven manufacturers, rubber is a responsible choice.

But Isn’t Plastic Cheaper? The Long-Term View

Yes, plastic often wins on upfront cost. Yet for performance-critical uses, rubber saves money over time:

Rubber hoses endure heat and pressure; plastic hoses crack and split prematurely.

Rubber bushings absorb noise and vibration seamlessly; plastic counterparts degrade unevenly under stress.

Rubber seals resist oils and corrosion; plastic seals fail faster, leaking fluids or breaking containment.

Cost isn’t just sticker price – it’s performance, lifespan, and reduced replacements. As one Rich-Rubber engineer notes: “Rubber components might cost more initially, but their durability typically lowers your lifetime costs.” Maintenance fleets, industrial plants, and automakers consistently validate this: rubber’s value compounds over years.

Where Rubber Grows: A Market Shift

Global demand reflects this shift. Despite supply-chain bumps, the synthetic rubber market is projected to reach $23.2 billion by 2026. Why?

Industries like electric vehicles (EVs) seek rubber’s vibration control and thermal stability for batteries and motors. Smart factories need resilient gaskets and dampeners that plastics can’t provide. Aerospace, renewables, and medical tech also lean into rubber for its safety-critical reliability.

The Takeaway: Two Materials, One Clear Winner for Tomorrow

Plastic still has its place – think cheap, single-use items or ultra-low-cost parts. But for engineers designing longevity, resilience, and eco-efficiency, advanced rubber stands unmatched.

Rich-Rubber and similar innovators are not just making “alternatives”… they’re redefining what materials can achieve. The future isn’t about replacing plastic everywhere. It’s about demanding more from materials – and rubber, built for performance and responsibility, answers that call.