Custom Molded Rubber Parts Upgrade for New Energy Vehicles: How Technological Innovation is Shaping the Future

HOME >> News >> Custom Molded Rubber Parts Upgrade for New Energy Vehicles: How Technological Innovation is Shaping the Future

News

Custom Molded Rubber Parts Upgrade for New Energy Vehicles: How Technological Innovation is Shaping the Future

Author: Site Editor Publish Time: 06-11-2025 Origin: Site

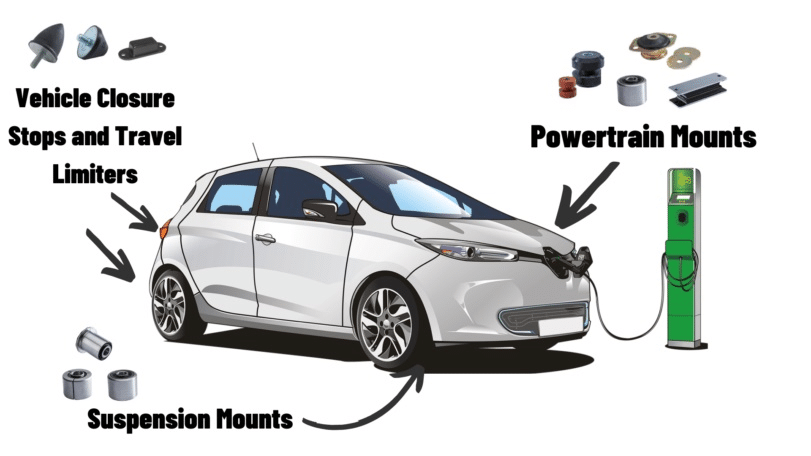

The rapid electrification of vehicles is driving revolutionary changes in chassis component engineering. As battery weight distribution, torque characteristics, and thermal management require fundamental redesigns, custom rubber molded parts – particularly vibration dampers and seals – are becoming pivotal performance differentiators.

Shifting Stress Landscapes

Modern NEV chassis face unprecedented demands:

- Vibration Complexity: Instant torque delivery creates torsional oscillations 300% higher than ICE vehicles

- Thermal Extremes: Battery proximity exposes components to sustained 140°C+ temperatures

- Weight Penalties: Suspension bushings must offset 600kg+ battery mass without adding volume

Technology Leap in Materials

Leading innovators now employ:

-

Multi-Axis Vibration Control

- Frequency-specific damping layers canceling 50-500Hz motor harmonics

- Carbon-nanotube reinforced EPDM achieving 40% wider temperature flexibility

-

Thermo-Regulating Seals

- Phase-change microcapsules absorbing heat spikes during DC fast-charging

- Dielectric-enhanced silicones preventing arcing in 800V architectures

-

Structural Intelligence

- Sensor-embedded air spring seals monitoring load distribution in real-time

- 3D-printed gradient foams optimizing stiffness-to-weight ratios

Global Validation Benchmarks

Progressive manufacturers now prioritize performance indicators absent from legacy standards:

- -40°C Cold-cycle Fatigue Resistance (validated per new Chinese GB/T 40718-2021)

- Electrochemical Compatibility to prevent seal degradation from leaked electrolytes

- Sodium Chloride Corrosion Immunity for coastal and winter-road conditions

The Next Frontier

Emerging requirements will accelerate material innovation:

▸ Solid-state battery compartments demanding ultra-low outgassing seals

▸ Torque vectoring systems requiring multi-directional bushing dampers

▸ Dynamic wheel loading (up to 2,300 N·m during regen braking) necessitating hybrid elastomer-metallic composites

Industry analysis suggests chassis rubber components now influence up to 17% of EV range through weight optimization and NVH management – transforming what was once a commodity part into a critical engineering platform.